Do printing friends know that there is a very important concept called “ICC curve”, this curve is not good, the color will be played out a relatively large deviation, affecting product quality. What is the ICC curve? Simply put, the ICC curve is the ink rationing scheme when a printer uses a certain ink and prints on top of a certain material. As we know, printing using cmyk four-color mode, several ink printing in the same area, due to the different ratios show different colors, we want the pattern. However, there are many kinds of ink, each ink and theoretical values are different, coupled with the different absorption of different printing materials vary, the color of the display and the formation of color differences between the picture. What to do? Manually make an ICC curve for the printout to solve. Usually, manufacturers in the UV printer before shipping will be for the customer’s processing situation to develop a specific program, from the characteristics of the machine, processing technology, processing materials, the use of ink in all aspects of the comprehensive, the performance of the machine tuned to the best. Unless there is a major change in the processing project, generally...

UV flatbed printer although you can print patterns on the surface of thousands of materials, but due to the characteristics of different material surfaces, UV ink adhesion, flexibility and other performance differences, will lead to peeling, peeling and other situations in some materials, which requires the use of UV coating to solve this problem.

We know that the uv printer is a high-tech plate free full-color digital printing machine, in the printing industry has a very wide range of applications, to know a uv printer is good, stable quality, in addition to the equipment board, guide, system, the most important is the printer nozzle. And currently applied to the uv printer printheads are many, mainly Kyocera, Ricoh, Seiko, Konica, Toshiba, Epson, etc. Today we will mainly talk about the performance of uv printers equipped with Ricoh printheads and its stability.

Every UV printer requires regular maintenance and care. If negligent maintenance, then it is likely to lead to nozzle infarction or other problems occur. As one of the central components of UV printers, changing a nozzle can easily be thousands of dollars. Therefore, good printhead maintenance and maintenance on the production of connectivity and improve economic efficiency is essential.

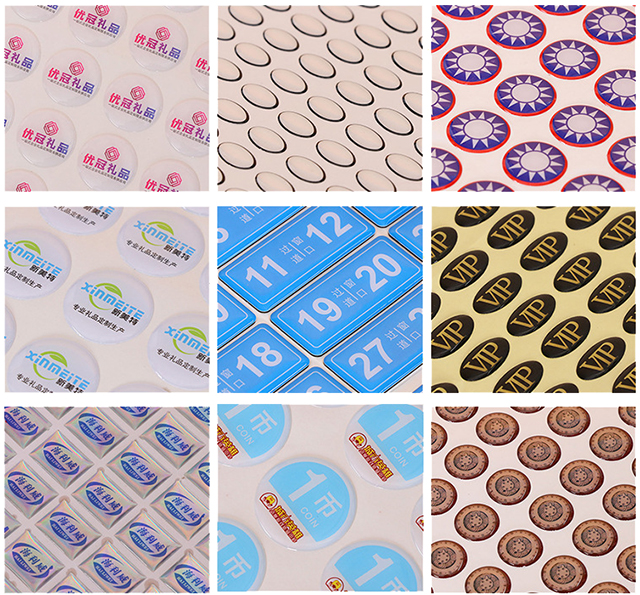

Can crystal labeling be printed with uv printer? The answer is: absolutely. What is crystal post? Crystal post is also called UV transfer paste, its predecessor is called sense pressure paste, it is in the special release material printed on the required graphics, and then cover the transfer film, and finally use the film to bring up the pattern transfer attached to the final product surface of a surface graphics production process. Crystal post in life has a wide range of applications, such as trademarks, signs and some electrical products surface decoration and so on. Crystal labeling printing effect picture Generally speaking, the production of crystal post business have these few characteristics, one is personalized; two is batch production; three is the pattern effect to be good; four is to be scratch-resistant and wear-resistant, which is very similar to the advantages of uv flatbed printer, and the traditional thermal transfer process is difficult to meet the requirements, so many manufacturers prefer to choose the advantages of more obvious uv flatbed printer. Ningbo Meixi CNC Technology Co., Ltd. is a high-tech enterprise specializing in the research and development, manufacture, sales and service of digital printing equipment.The company’s products are widely used...

Meixi UV flatbed printer full models using cold light source UV-LED system curing, longer life, more energy efficient and power saving, printing instant drying, to expand the scope of application of the printer material, full models using the head anti-collision configuration, in order to provide you with better printing help at the same time, to ensure the safety of the print nozzle, reduce your use of UV machines on the nozzle loss. printers use environmentally friendly UV curing ink adapted to Ricoh printheads as standard, and are equipped with a secondary cartridge heating function to ensure fast printing while ensuring that the ink does not solidify, thereby reducing the appearance of printing failures.